TEQOIA, the specialist in automation for the egg industry. Smart solutions for farms, grading stations, and industrial processing. Focused on egg handling and quality. Always one step ahead, we call that egg handling with vision.

We are a Dutch machine builder and system integrator in the egg industry. With smart, reliable solutions, we make production processes more efficient, sustainable, and futureproof. From innovative case packers to palletizers: delivered worldwide with professional installation and service. With technology, precision, and partnership, we are building the egg industry of tomorrow.

More information

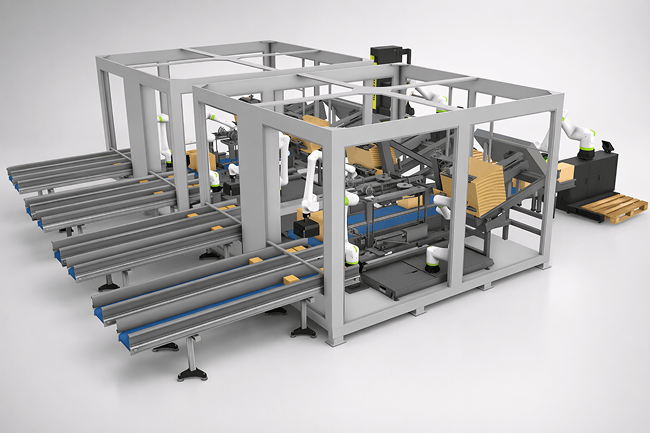

Our Casepacker brings together the complete packaging process in one compact and intelligent machine. From automatically unfolding the box and filling it with small egg packages to accurately placing the filled boxes on a pallet: the entire process runs seamlessly within one integrated system.

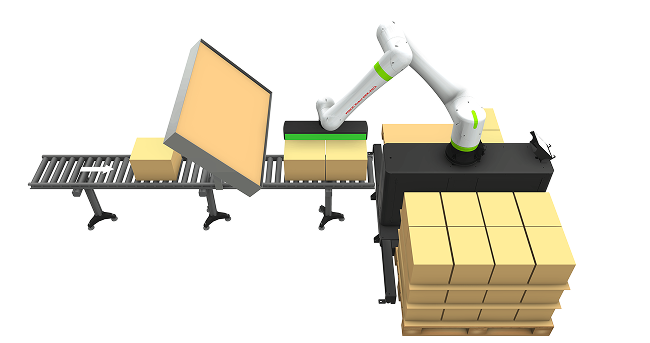

The MH300 Gripper is designed for precision handling of open-top boxes. Its compact, modular design allows for quick integration into existing lines and easy relocation across production sites.

Application: Ideal for fragile or irregularly shaped products, ensuring safe top-pick placement every time.

Flexibility: Smart software recipes handle multiple box types and patterns without manual changeover.

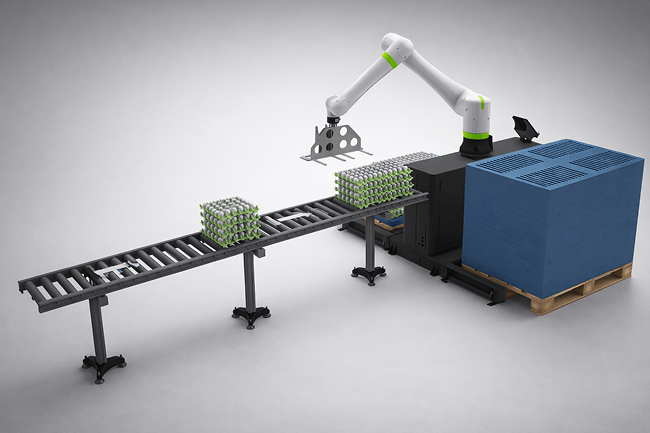

The MH300 Vacuum is built for gentle handling of closed-top boxes and delicate products. Its standardized design allows for rapid deployment and minimal line modifications.

Application: Equipped with a vacuum gripper for secure handling of fragile items or sealed packaging.

Flexibility: Top-pick placement ensures packages remain intact while maintaining high throughput.

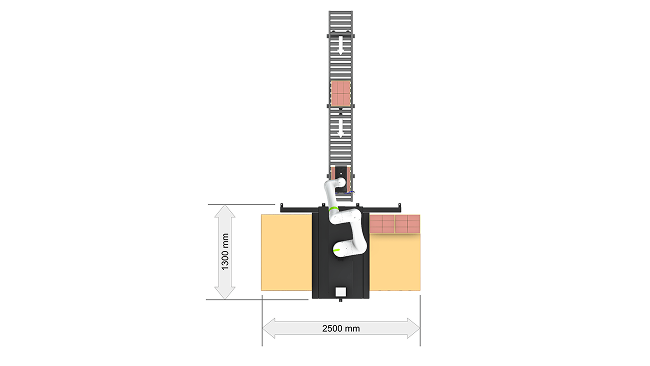

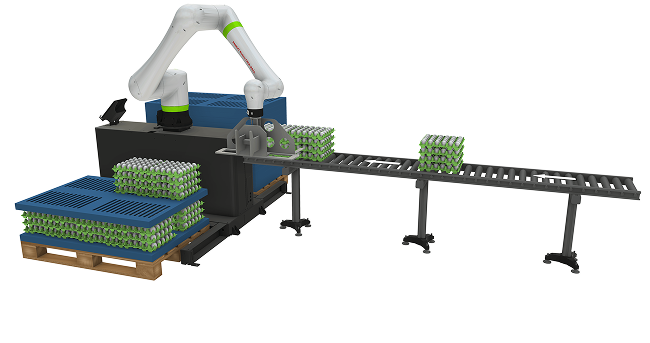

The GB100 Palletizer is the ultimate solution for farms looking to automate their end of line process without sacrificing space. By integrating vision technology, the system accurately identifies and places crates or trays, ensuring a seamless flow from the grader to the pallet.

Our RT40 case erector brings the entire box unfolding process together in one compact and intelligent machine. The machine automatically unfolds the box, tapes the bottom, and places it onto your conveyor or machine, suitable for virtually any box size.

From automatic pallet outfeeds to complete conveyor and transport systems, we support you from initial concept through to final implementation. Do you have specific requirements or challenges within your production environment? Our engineering team can design, draw, and develop tailor made solutions, including customer-specific specials.

We handle the installation of our machines and systems in-house, supported by a carefully selected network of local partners. This allows us to operate efficiently worldwide while maintaining high quality standards. We believe the best service is driven by in-depth market knowledge.

We don't just deliver technology; we build long-term partnerships with reliable service as the foundation.